Riseria Pasini was founded in 1948 by three brothers Bruno, Arnaldo and Ciro in Villa Garibaldi di Roncoferraro, a town located in the hub of the rice fields (paddy fields) in the province of Mantova which is in the heart of the region known as the Pianura Padana. In this region rice by tradition has been cultivated for centuries.

Thanks to the commitment and expertise, distinct qualities of this company, rice milling and sales increased constantly and in 1960 the company, to meet demand, built a new milling and processing plant transforming a family run enterprise into an industry. In the 80’s the children of the three brothers joined the company and together increased the annual production of white rice to over 10,000 tonnes.

The undisputed quality of the rice and the significant technological innovations introduced into production and processing led Riseria Pasini to expand business nationwide positioning this company, in the 90’s, as market leader in the Veneto Region. The company today is run by the third generation of this family.

A renewed entrepreneurial spirit and family management guarantee expert and specialist research in offering a quality product and an enterprise focused on satisfying consumer demand and expectations.

HISTORY

On Italian dinner tables

since 1948.

RICE

The most widely-consumed

cereal grain in the world.

Rice is a member of Gramineae grass family (Oryza Sativa). Originally from Asia, rice was first imported to Italy by the Romans who, due to its high cost, used it primarily for producing medicines and cosmetics. It was only in the 16th Century that rice was cultivated as a food product, above all in the northern regions of Italy.

In the years running up to the second world war the production of rice began on an industrial scale.

Rice is sown in spring and the rice plants are ready for harvest after 5-6 months. Harvest is at the end of summer beginning of autumn. Once the paddy rice has been dried it is stored in silos even up to several months. Cultivation and milling are two completely separate processes: there are very few companies that cultivate their own rice to then mill and process it.

Rice is a genuine and staple food product and the nutritional properties are due to the high starch content (over 90% in the milled grain) with no waste. Rice is also rich in mineral salts, vitamins and proteins. Ideal for maintaining a healthy diet.

There are various qualities of rice which are divided between 2 major subspecies:

Japonica

COMMON RICE

small round grain soft texture when cooked.

Ideal for broths, desserts and cakes

FINE RICE

medium sized slender grain.

Keeps texture and shape when cooked and ideal for making rice timbales and croquettes

RISO FINO

chicco di medie dimensioni e affusolato. Resistente alla cottura, è consigliato per timballi e supplì

SUPER-FINE RICE

large long grains. Keeps a firm al dente texture and shape when cooked.

Indica

SUPER-FINE THAI RICE

long slender grain. Does not keep a firm texture when cooked and is recommended for preparing ethnic dishes and for serving with main courses.

RICE MILLING

Technology, automation and

respect for the environment.

Milling is also known as dehulling which comes from the word hull which is outer part of the grain (chaff) which since the 16th century up to industrialisation is the process which removes the hull. Milling can be divided into two stages: the first stage is cleaning and dehulling in this way waste products as stones, metals, seed, straw are removed, then the bran coat, the protective layer, and non-mature grains (green grains) are removed. At the end of this stage we have “brown” rice, very rich in nutritional properties. The second stage is know as polishing and at this point in the process stained or fragmented grains are separated and removed. It is very important when polishing to take care not to damage the rice grains. Polishing is a mechanical rubbing process which removes outer layers (integuments) known as the bran coat (pericarps) until the grain becomes it characteristic white colour. An optical selector is used for quality control which is a technologically advanced piece of machinery which “scans” each single grain eliminating stained or damaged grains or any impurities.

At this point in the process the rice is ready for being packaged and packed. When preparing parboiled rice, the paddy rice is subjected to a specific steaming process: the paddy rice is soaked in water (maceration) for a period of time in purpose tanks, then steamed cooked under pressure in an autoclave and finally dried and dehulled. This parboiling process drives nutrients such as mineral salts and vitamins found in the bran coat into the grains together with water. These nutrients remain trapped within the grain even after polishing. This process increases the nutritional properties of rice, it also makes it easier to digest and reduces the absorption capacity in this way the rice can be cooked for longer maintaining a firm al dente texture. The grains have an amber and glassy appearance having absorbed the yellow straw colour of the bran coat.

STERILISATION

for improved product

preservation

Food products have always been at risk of deterioration and infestation. Up until now toxic substances have been used to destroy insects, larvae and eggs. So that is why, in recent years, increasing attention has been focussed on respecting the environment and looking after consumer health, with poisons that were too aggressive yet guaranteed excellent results being banned as a result. Unfortunately, new insecticides are still not effective enough and so rice grains are potentially infested with larvae and eggs that tend to hatch out in the right climactic conditions. Vacuum packing technology certainly ensures excellent husked rice preservation, but cannot be applied to formats greater than 1 kg. Vacuum packing has another flaw, not always welcomed by keen chefs. A faint stuffy odour is released when the bag is opened, due to the lack of air inside.

Nowadays people are becoming more interested in natural products that transmit values based on respecting the environment and sustainable agricultural and industrial production. People are after a “made like it used to be” artisan product that still offers guarantees of safety that only modern machinery can provide. All of this is now finally possible with our sterilising system, one of the few in the world that destroys the microscopic eggs contained in rice grains, thus eliminating the possibility of infestations that usually occur in warmer periods. After years of research and development we are proud to present a new line of products that responds to the requirements of a consumer segment which keeps growing day by day, combining healthy produce with long term preservation.

DATA

7.000

kilogrammes/hour

of paddy rice milled

5

ultra-modern

packaging lines

5.000

square metres of

covered factory space

RISO PASINI

a wide range of only

the best rice

ARBORIO

Long-grain superfine rice. Ideal for preparing any kind of dry rice. Italy's most widely used rice variety.

ROMA

Long-grain superfine rice. Used for risottos and the best rice for arancini.

BROWN

Half-milled fine rice. Lots of fibre, highly nutritious. Ideal for sports enthusiasts or those on a diet.

VIALONE NANO

Medium-grain rice with large, round grains that readily absorbs flavours while remaining al dente. Perfect for every kind of risotto.

BASMATI

Superfine rice with long, slender grains. Grown in India and Pakistan. Appreciated for its fragrance and delicate flavour.

CARNAROLI

Long-grain superfine rice. Ideal for creamy risottos and timbales because of its resistance to overcooking.

RIBE PARBOILED

This quicker-cooking fine rice is produced via a process that enriches the grains with the vitamins contained in the bran and gives it its amber appearance.

BLACK

Dark-coloured, strongly-flavoured brown rice. Originally from China, it is now also grown in Italy. Ideal for refined and impact dishes.

RIBE

Medium-grain fine rice. Suited to every kind of dish. Ideal for timbales and al dente pilaf rice.

SUSHI

Italian round-grain rice with clear, round grains. Cooks rapidly. Recommended for preparation of traditional Japanese dishes.

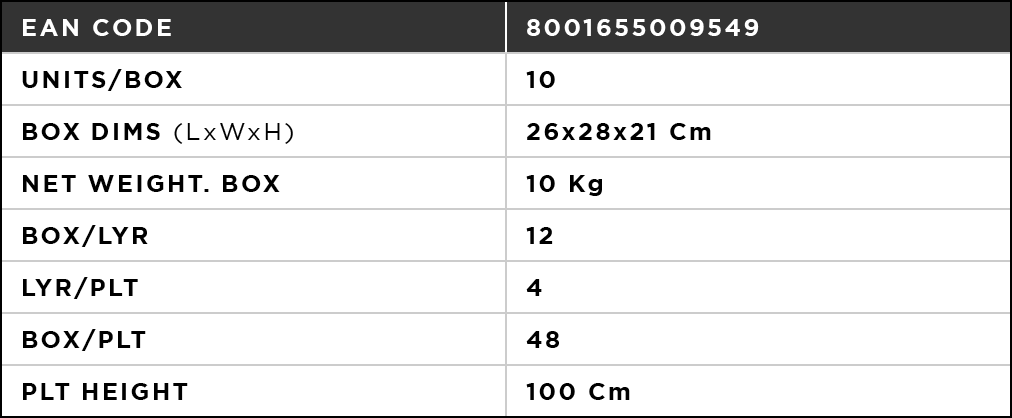

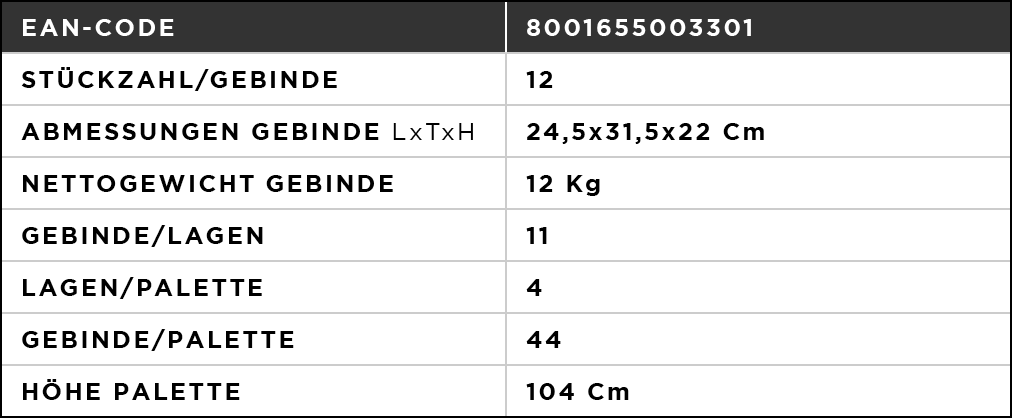

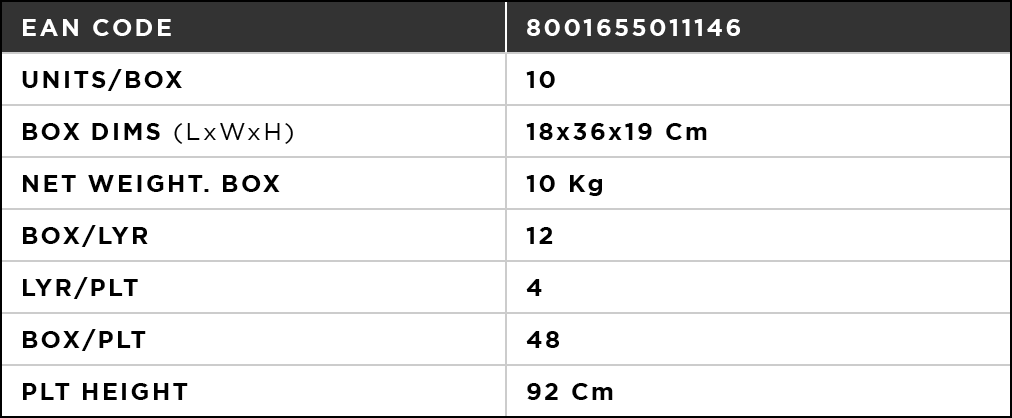

RISO PASINI

1 kg vacuum bag in box

CARNAROLI GRAN RISERVA

1 KG CARNAROLI GRAN RISERVA RICE – AGED 18 MONTHS

VACUUM BAG IN BOX

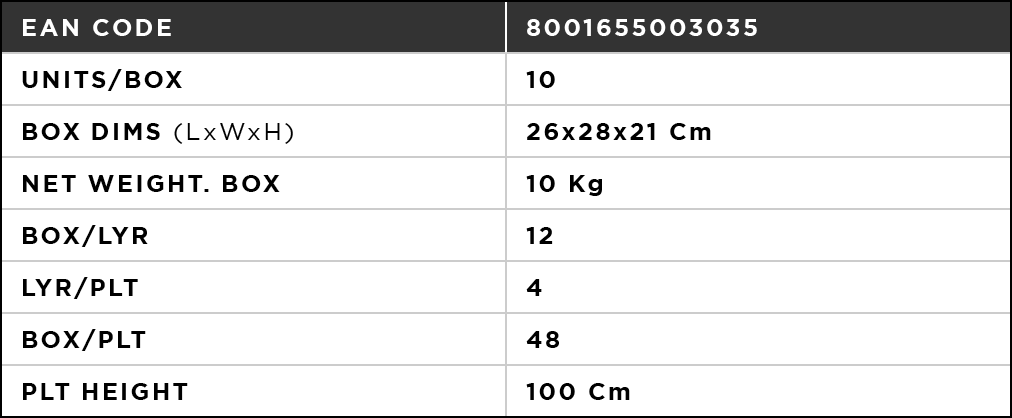

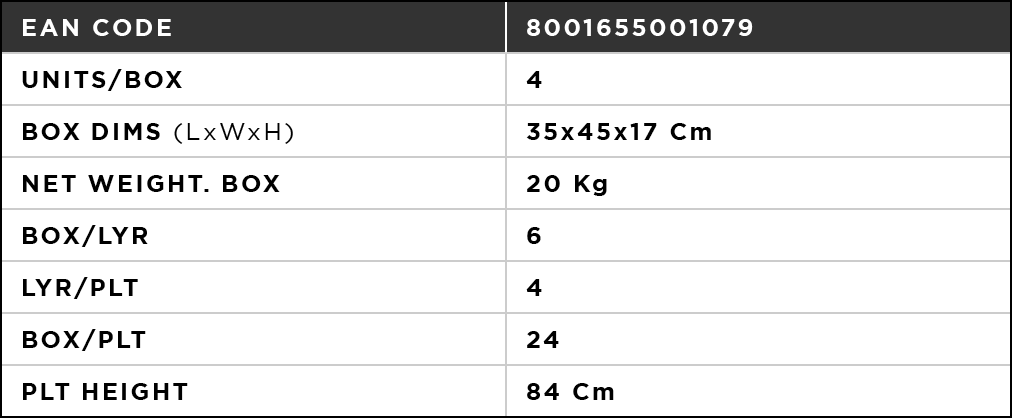

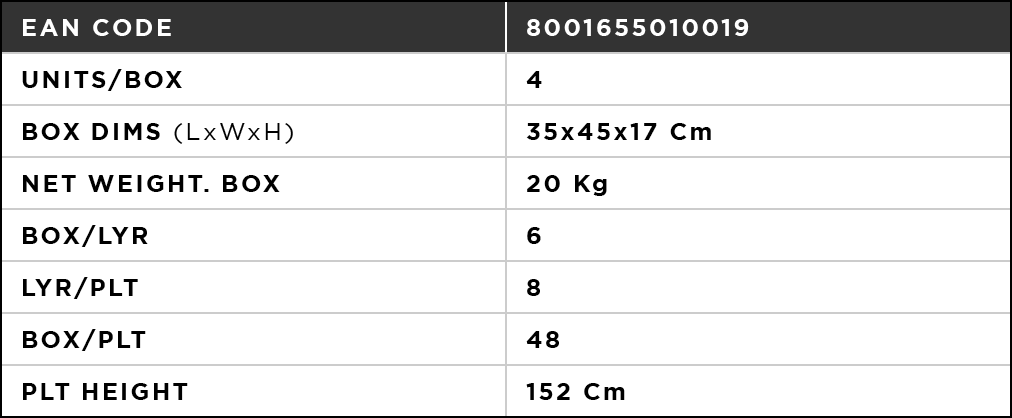

RISO PASINI

1 kg vacuum bag without box

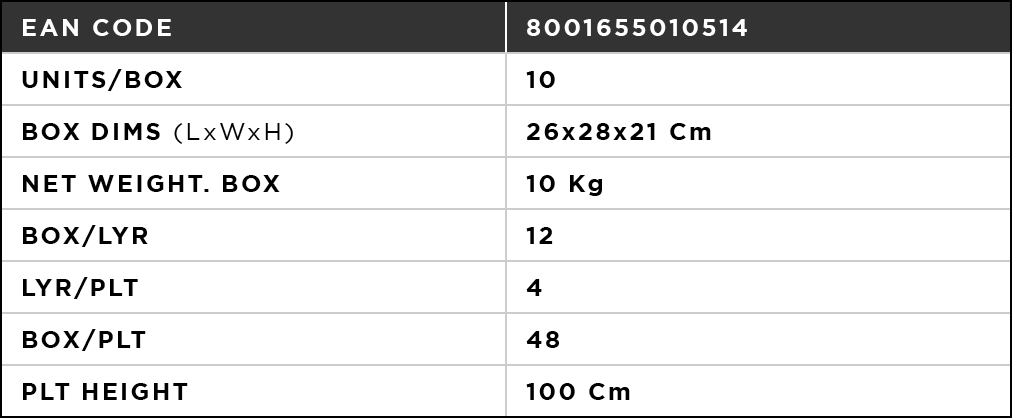

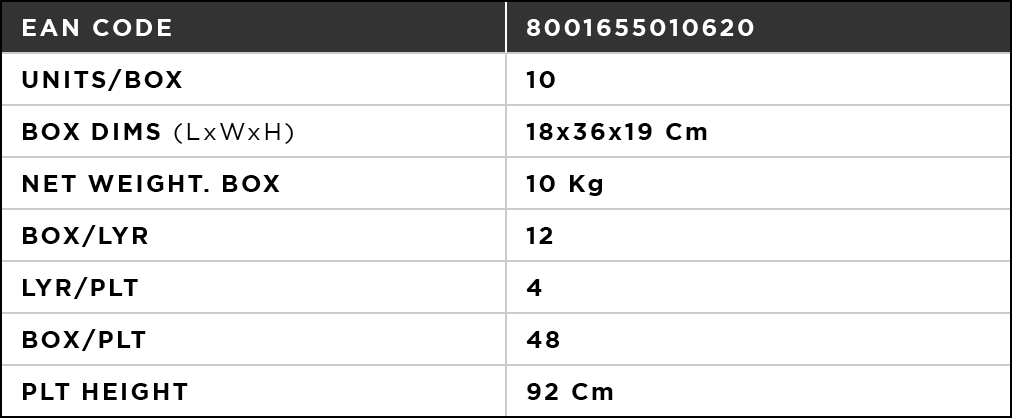

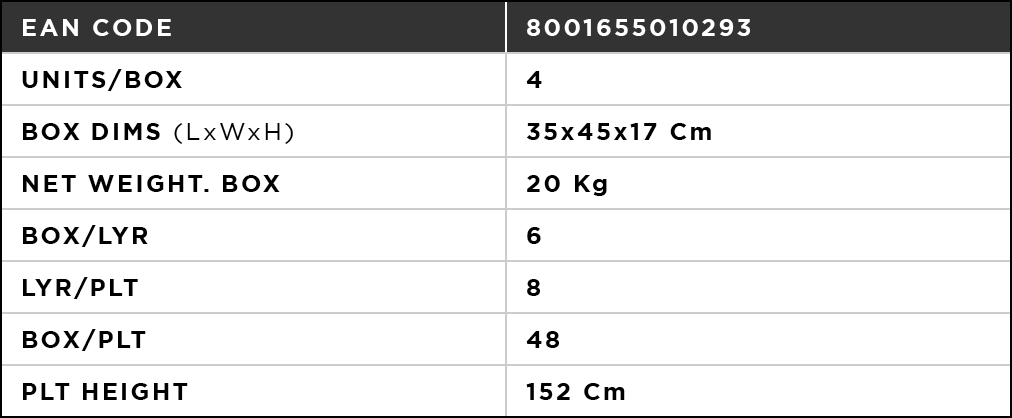

RISO PASINI

1 KG PAPER BAG

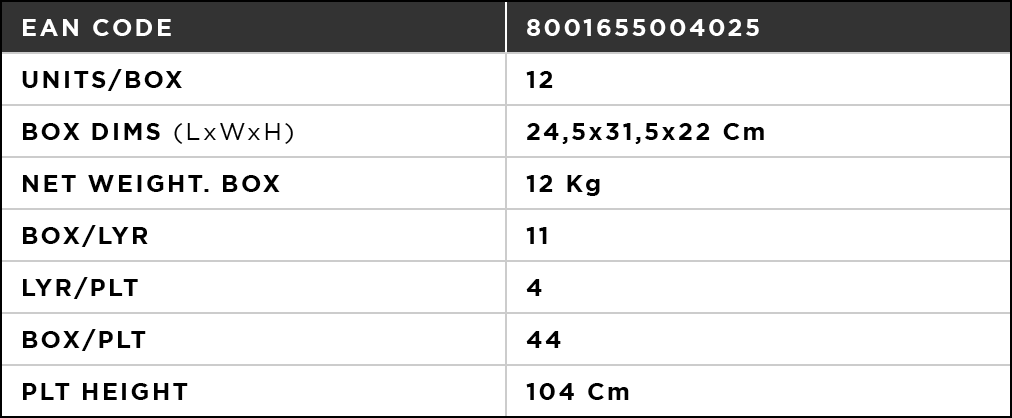

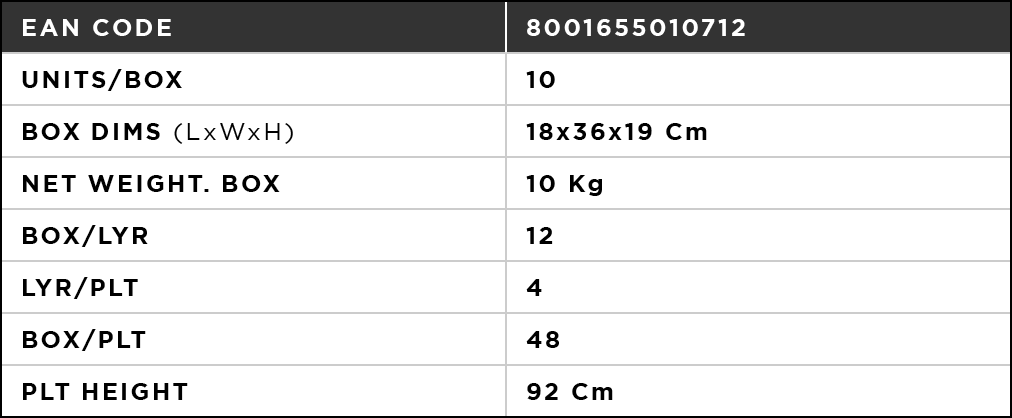

RISO PASINI

500g DOUBLE SQUARE BOTTOM

RISO PASINI

5 kg PILLOW BAG

FUKISHI

SUSHI RICE

Kundal

Basmati

GRANRISO

A vast selection of rice types for

even more successful recipes

ARBORIO

Long-grain superfine rice. Ideal for preparing any kind of dry rice. Italy's most widely used rice variety.

BASMATI

Superfine rice with long, slender grains. Grown in India and Pakistan. Appreciated for its fragrance and delicate flavour.

RIBE

Medium-grain fine rice. Suited to every kind of dish. Ideal for timbales and al dente pilaf rice.

ORIGINARIO

Italian round-grain rice with clear, round grains. Cooks rapidly and is recommended for puddings and soups.

THAIBONNET PARBOILED

This quicker-cooking fine rice is produced via a process that enriches the grains with the vitamins contained in the bran and gives it its amber appearance.

CARNAROLI

Long-grain superfine rice. Ideal for creamy risottos and timbales because of its resistance to overcooking.

ROMA

Long-grain superfine rice. Used for risottos and the best rice for arancini.

VIALONE NANO

Medium-grain rice with large, round grains that readily absorbs flavours while remaining al dente. Perfect for every kind of risotto.

THAIBONNET

Superfine rice with long, slender grains. Originally from China, it is now also widely grown in Italy.

GRANRISO

1 kg standing bag

GRANRISO

5 kg PILLOW BAG

GRANRISO

25 kg PILLOW BAG

Private Label

With 5 modern integrated and automated packaging lines, the company is able to offer a complete range of products packaged in the most disparate formats: vacuum bag with or without box, bags by 500 g, 1 and 5 kg, bags by 25 kg, 1000 kg big bag. We can package your BRAND in various formats, offering a fast, certified and flexible service.

INDUSTRIAL PRODUCTS

New big bag and bulk freight tanker fill ing systems allow us to handle the requirements of the food and cosmetics industry, providing not only rice but also selected broken rice, rice bran and rice husks.

Riseria Pasini s.r.l.

VIA C. BATTISTI, 288

46037 VILLA GARIBALDI

MANTOVA – IT

Tel e Fax +39.0376.663164 — info@risopasini.com

VAT No. 00138650205